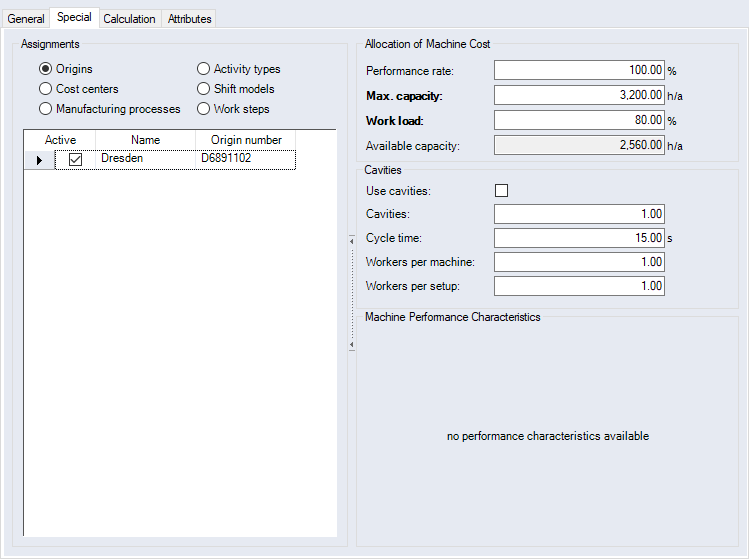

Special tab

Figure: "Data Administration" dialog, "Machines" category, "Special" tab

"Assignments" group:

| Option | ||

| Origin | Multiple locations can be added but only one can be actively assigned. A location is included in the machine cost calculation because it provides the location-dependent costs (e.g. energy costs or water costs). | |

|

|

Cost Centers | Multiple cost centers can be added but only one can be actively assigned. If a cost center is assigned to a machine, then the costs of the machine are used completely from the cost center. You cannot enter any more costs for the machine. |

|

|

Manufacturing Processes | Multiple manufacturing processes can be added and multiple ones can be actively assigned. If one of the linked processes is assigned within a project, FACTON will ask whether the linked machines shall also be copied. |

| Activity type | Multiple activity types can be added and multiple ones can be actively assigned. An assignment enables you to limit the activity types when assigning the Cost Center Calculation Mode to a process in the "Cost Center" dialog within a project. | |

| Shift Models | Multiple shift models can be added but only one can be actively assigned. Making an assignment displays information about the machine's capacity for the cost calculation. | |

| Work steps | Multiple work steps can be added and multiple ones can be actively assigned. Linking makes it possible to restrict the selection when assigning work steps to the machine to those work steps that are linked in a project. | |

"Allocation of Machine Cost" group

| Entry field | |

| Performance rate | A factor is specified here that is multiplied by the max. capacity. This factor is indicated as a percentage and is 100% by default. You can administer the respective rights here. |

| Max. capacity | If a shift model is linked and activated to this machine, the value of the max. capacity is used and the available capacity is calculated based on this. |

| Work load | Similar to the performance rate, a machine utilization factor is specified here that is multiplied by the max. capacity. If the allocation is not set to the shift model, this factor is calculated. You can administer the respective rights here. |

| Available capacity | Calculates the current occupancy of the machine |

"Cavities" group:

| Checkbox | |

| Use cavities | When the checkbox is activated, the use of cavities is automatically activated in the "Cost Center" dialog when the cavities are retrieved from the cost center using the Cost Center Calculation Mode . You can administer the respective rights here. |

| Entry field | |

| Cavities | Shows the number of used cavities. |

| Cycle time | Shows the time required for the entered number of cavities. |

| Employees per machine | Displays the number of required operators (employees) for the entered number of cavities. |

| Employees per setup | The number of required adjusters (employees related to setup) for the given number of cavities. |

"Machine Performance Characteristics" group:

These parameters are used to classify the machine and can be used in Technology mode, for example. Unlike the calculation parameters, they do not belong to the standard for calculating the machine hour rate. Therefore, the dialog window initially has no entry fields.

Further Information