Specify Processes

In this section, additional calculation elements required to calculate the costs will be inserted into and specified within the inserted processes for the »Motor Shaft«.

Sequence

Specify »Setup Process - Turning«

- In the Structure view, select

»Setup Process - Turning«.

- In the Structure view, select

»Setup Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Setup Operator to insert a setup operator.

Setup Operator to insert a setup operator. - In the Details ► Overview view schema (combobox), enter values for the following properties:

| Comment | Fitter |

| Calculation | |

| Labor Group | EG06 |

| Number of Workers | 2 |

| Tie Up Rate at Process | 50 % |

For multiple use of a previously inserted global project element (e.g. the same machine, since the investment costs should only be introduced to the calculation once) you can insert these as follows:

Reuse Global Calculation Elements Multiple Times

- You are logged in as a Calculator.

- You are in the Calculations workspace.

- You are in the Structure view.

- In the Structure view, select the global calculation element you wish to reuse.

- Click in the first empty field in front of the calculation element and drag & drop it.

- while pressing ALT to insert the global calculation element again as Link (see Insert Global Calculation Element).

The mouse cursor displays the following icon:

or

- CTRL to insert the global calculation element again as Copy.

The mouse cursor displays the following icon:

- while pressing ALT to insert the global calculation element again as Link (see Insert Global Calculation Element).

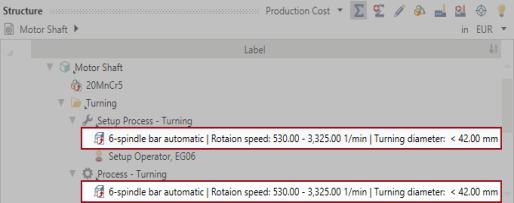

Specify »Process - Turning«

-

Insert the same

Insert the same  machine as in the »Setup Process - Turning« as Link to reuse the machine.

machine as in the »Setup Process - Turning« as Link to reuse the machine.

Reuse Global Calculation Elements Multiple Times

- You are logged in as a Calculator.

- You are in the Calculations workspace.

- You are in the Structure view.

- In the Structure view, select the global calculation element you wish to reuse.

- Click in the first empty field in front of the calculation element and drag & drop it.

- while pressing ALT to insert the global calculation element again as Link (see Insert Global Calculation Element).

The mouse cursor displays the following icon:

or

- CTRL to insert the global calculation element again as Copy.

The mouse cursor displays the following icon:

- while pressing ALT to insert the global calculation element again as Link (see Insert Global Calculation Element).

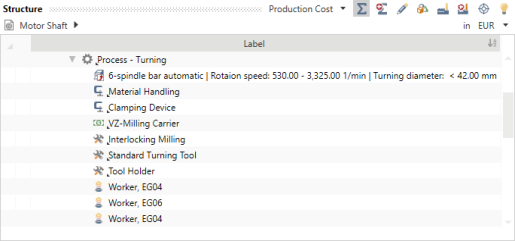

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Fixture to insert a local fixture.

Insert New Local Fixture to insert a local fixture. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Fixture to insert a local fixture.

Insert New Local Fixture to insert a local fixture. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Special Direct Cost to insert a local special direct cost.

Insert New Local Special Direct Cost to insert a local special direct cost. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Tool to insert a local tool.

- In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Tool to insert a local tool.

- In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Tool to insert a local tool.

- In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Process - Turning«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

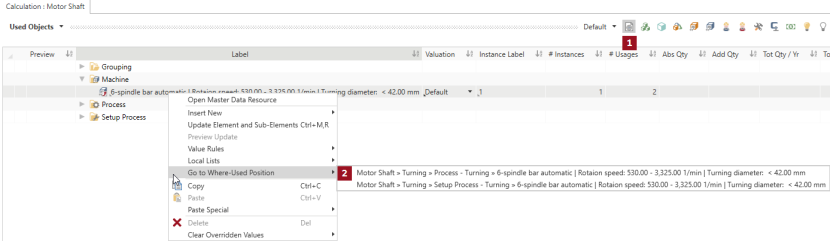

In the Used Objects view, you can verify whether you have used the same machine for »Setup Process - Turning« and »Process - Turning«. The following two points indicate this:

| Label | Material Transport |

| Equipment is specific |

|

| Calculation ► Number of Fixtures | |

| Equipment Is Used Over Production Lifetime |

|

| Lifetime | 150,000 cycles |

| Calculation ► Investment | |

| Purchase Value | 2,000 EUR |

| Incidental Acquisition Cost | 200 EUR |

| Label | Clamping Device |

| Equipment is specific |

|

| Calculation ► Number of Fixtures | |

| Equipment Is Used Over Production Lifetime |

|

| Lifetime | 430,000 cycle |

| Calculation ► Investment | |

| Purchase Value | 1,000 EUR |

| Incidental Acquisition Cost | 100 EUR |

| Label | VZ – Milling Carrier |

| Calculation | |

| Number of Units | 1 |

| Costs per Unit | 4,800 EUR |

| Label | Interlocking Milling |

| Equipment is specific |

|

| Calculation ► Investment | |

| Purchase Value | 800 EUR |

| Label | Standard Turning Tool |

| Equipment is specific |

|

| Calculation ► Number of Tools | |

| Equipment Is Used Over Production Lifetime |

|

| Lifetime | 350,000 cycle |

| Calculation ► Investment | |

| Purchase Value | 50 EUR |

| Label | Tool Holder |

| Equipment is specific |

|

| Calculation ► Investment | |

| Purchase Value | 80 EUR |

| Comment | Machine operator |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

| Personal Allowance Rate | 55 % |

| Comment | Mechanical Engineer |

| Calculation | |

| Labor Group | EG06 |

| Number of Workers | 1 |

| Comment | QA Running Control |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

Specify Process »Washing«

- In the Structure view, select

»Washing«.

- In the Structure view, select

»Washing«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Washing«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Technical Measure (Cycle) to insert a local technical measure.

Insert New Local Technical Measure (Cycle) to insert a local technical measure. - In the Details ► Overview view schema (combobox), enter values for the following properties:

| Comment | Machine operator |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

| Personal Allowance Rate | 55 % |

| Label | Technical Measure |

| Responsible | John Doe |

| Implementation Time Horizon | Mid-Term |

| Implementation Level | IL1 – Idea defined |

| Effective from | 8/18/2018 |

| Calculation | |

| Measure value cycle time | 2 s / cycle |

Specify Process »Hardening«

- In the Structure view, select

»Hardening«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Machine to insert a local machine.

- In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select

»Hardening«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

| Label | Furnace | max. load: 550 kg |

| Calculation ► Investment | |

| Purchase Value |

|

| Installation Cost |

|

| Residual Value |

|

| Calculations ► Fixed Machine Cost | |

| Depreciation Period | 8 a |

| Calculation view schema (combobox) ► Fixed Machine Cost ► Fixed Machine Cost - Details | |

| Footprint | 10 m² |

| Proportionate Area | 15 % |

| Calculations ► Variable Machine Costs | |

| Connected Load | 104.80 kW |

| Comment | Machine operator |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

Specify »Process - Grinding«

- In the Structure view, select the

»Setup Process - Grinding«.

- In the Structure view, select the

»Setup Process - Grinding«.

- In the ribbon, click on Edit ► Insert ►

Setup Operator to insert a setup operator.

Setup Operator to insert a setup operator. - In the Details ► Overview view schema (combobox), enter values for the following properties:

| Comment | Fitter |

| Calculation | |

| Labor Group | EG06 |

| Number of Workers | 1 |

Specify »Process - Grinding«

- In the Structure view, select the

»Process - Grinding«.

-

Insert the same

Insert the same  machine as in the »Setup Process - Grinding« as Link to reuse the machine.

machine as in the »Setup Process - Grinding« as Link to reuse the machine.

Reuse Global Calculation Elements Multiple Times

- You are logged in as a Calculator.

- You are in the Calculations workspace.

- You are in the Structure view.

- In the Structure view, select the global calculation element you wish to reuse.

- Click in the first empty field in front of the calculation element and drag & drop it.

- while pressing ALT to insert the global calculation element again as Link (see Insert Global Calculation Element).

The mouse cursor displays the following icon:

or

- CTRL to insert the global calculation element again as Copy.

The mouse cursor displays the following icon:

- while pressing ALT to insert the global calculation element again as Link (see Insert Global Calculation Element).

- In the Structure view, select the

»Process - Grinding«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Fixture to insert a local fixture.

Insert New Local Fixture to insert a local fixture. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select the

»Process - Grinding«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Tool to insert a local tool.

- In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select the

»Process - Grinding«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select the

»Process - Grinding«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select the

»Process - Grinding«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

| Label | Clamping Device |

| Equipment is specific |

|

| Calculation ► Number of Fixtures | |

| Equipment Is Used Over Production Lifetime |

|

| Lifetime | 350,000 cycle |

| Calculation ► Investment | |

| Purchase Value | 1,600 EUR |

| Incidental Acquisition Cost | 160 EUR |

| Label | Grinding Wheel (CBN) |

| Equipment is specific |

|

| Calculation ► Number of Tools | |

| Equipment Is Used Over Production Lifetime |

|

| Lifetime | 200,000 cycle |

| Calculation ► Investment | |

| Purchase Value | 7,800 EUR |

| Comment | Machine operator |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

| Comment | Mechanical Engineer |

| Calculation | |

| Labor Group | EG06 |

| Number of Workers | 1 |

| Comment | QA Running Control |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

Specify Process »Washing & Preserve«

- In the Structure view, select the

process »Washing & Preserve«.

-

Insert the same

Insert the same  machine as in the process »Washing« as Link to reuse the machine.

machine as in the process »Washing« as Link to reuse the machine.

Reuse Global Calculation Elements Multiple Times

- You are logged in as a Calculator.

- You are in the Calculations workspace.

- You are in the Structure view.

- In the Structure view, select the global calculation element you wish to reuse.

- Click in the first empty field in front of the calculation element and drag & drop it.

- while pressing ALT to insert the global calculation element again as Link (see Insert Global Calculation Element).

The mouse cursor displays the following icon:

or

- CTRL to insert the global calculation element again as Copy.

The mouse cursor displays the following icon:

- while pressing ALT to insert the global calculation element again as Link (see Insert Global Calculation Element).

- In the Structure view, select the

process »Washing & Preserve«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

| Comment | Machine operator |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

Specify Process »Remaining Dirt«

- In the Structure view, select the

process »Remaining Dirt«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Machine to insert a local machine.

- In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select the

process »Remaining Dirt«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

| Label | Residual Dirt Facility |

| Calculation ► Investment | |

| Purchase Value |

|

| Installation Cost |

|

| Residual Value |

|

| Calculations ► Fixed Machine Cost | |

| Depreciation Period | 8 a |

| Comment | Machine operator |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

Specify Process »Packaging & Goods Leaving Inspection«

- In the Structure view, select the

process »Packaging & Goods Leaving Inspection«.

- In the Structure view, select the

process »Packaging & Goods Leaving Inspection«.

- In the ribbon, click on Edit ► Insert ►

Worker to insert a worker.

Worker to insert a worker. - In the Details ► Overview view schema (combobox), enter values for the following properties:

- In the Structure view, select the

process »Packaging & Goods Leaving Inspection«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Fixture to insert a local fixture.

Insert New Local Fixture to insert a local fixture. - In the Details ► Overview view schema (combobox), enter values for the following properties:

-

Label Standard Measuring Device Equipment is specific

Calculation ► Investment Purchase Value 2,000 EUR - In the Structure view, select the

process »Packaging & Goods Leaving Inspection«.

- In the ribbon, click on Edit ► Insert ►

Insert New Local Special Direct Cost to insert a local special direct cost.

Insert New Local Special Direct Cost to insert a local special direct cost. - In the Details ► Overview view schema (combobox), enter values for the following properties:

| Comment | Final Inspection and Packers |

| Calculation | |

| Labor Group | EG04 |

| Number of Workers | 1 |

| Label | SEK – For Internal Transport |

| Calculation | |

| Number of Units | 325 |

| Costs per Unit | 15 EUR |

Save and Publish Changes

Save Changes

- In the quick access toolbar, click the

Save all applications data button.

All of your changes are saved and the icon is grayed-out.

Alternative:

- In the ribbon, click on the File ► Save All.

All changes are saved.

Publish Changes

- In the ribbon, click on the File ► Publish All.

All existing changes are published.

It is not possible to undo changes after publishing.

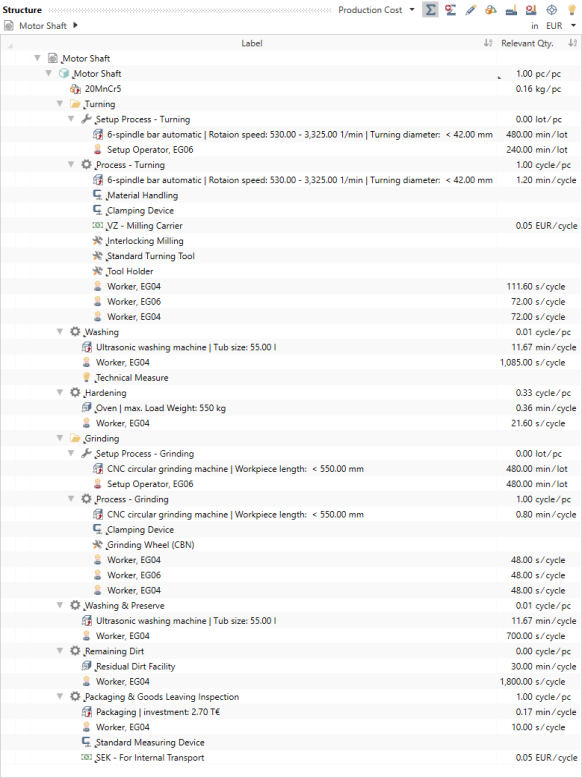

When you have correctly entered all data, check the Key Figures ►Production Cost - Detailed view schema for the Imputed Sales Price 7.30 EUR / pc.

The value depends on the current status of the FACTON Benchmark data and may deviate slightly.