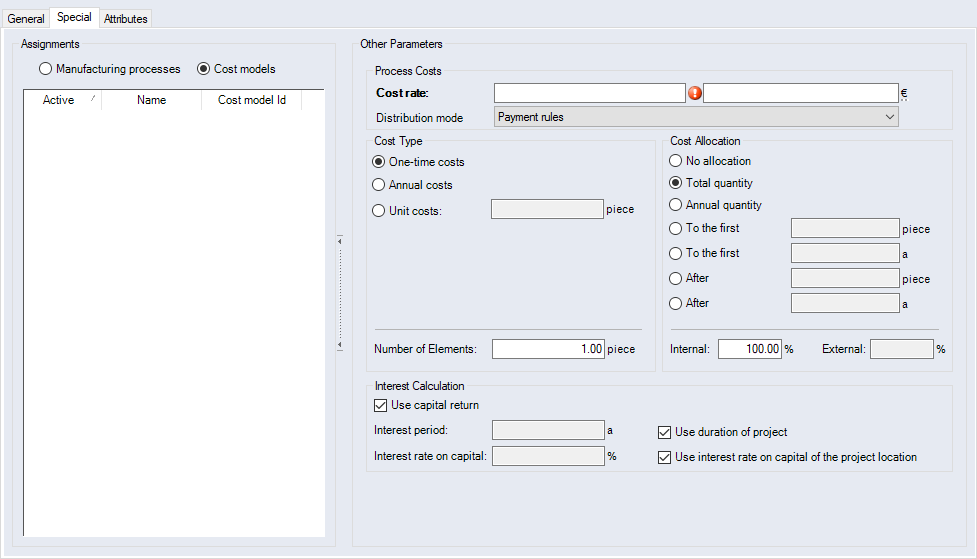

"Special" tab

This tab is used to define cost rates, cost types, and cost allocation types for additional costs.

Figure: "Data Administration" dialog, "Additional Costs" category, "Special" tab

"Assignments" group

| Option | Description |

|---|---|

| Manufacturing Processes | Multiple manufacturing processes can be added and multiple ones can be actively assigned. If a process is assigned in a project, a prompt will be displayed asking whether the linked additional costs should be applied. |

| Cost Models | Only one cost model can be linked and actively assigned. |

"Process Costs" group

| Entry field | |

| Cost rate |

Enter the cost rate value.

|

| Combobox | |

| Distribution mode |

Select the cash flow course per additional cost element. The distribution mode determines how the cash flow is being distributed over the investment period/project period.

|

"Cost Type" group

| Option | |

| One-time costs | When this option is selected, the additional costs are only incurred and included once in the calculation. Entering the "Number of Elements" is possible. |

| Annual costs | When this option is selected, the additional costs are only incurred and included annually in the calculation. Entering the "Number of Elements" is possible. |

| Unit costs | When this option is selected, the quantity of the additional costs can be entered. The costs of the additional costs are incurred and included in the calculation for the quantity entered. The additional cost quantity results from: Entering the "Number of Elements" is possible. |

| Entry field | |

| Number | Shows how often the costs are included in the additional costs. |

"Cost Allocation" group

| Option | |

| No allocation | When selected, additional costs are not allocated. |

| Total quantity | When selected, the additional costs are allocated to the total quantity. |

| Annual quantity | When selected, the additional costs are allocated to the annual quantity. |

| To the first ... piece | Selecting this option allows you to enter a quantity the additional costs can be allocated to - beginning with the SOP. |

| To the first ... a | Selecting this option allows you to enter the years the additional costs can be allocated to - beginning with the SOP. |

| After ... piece | Selecting this option allows you to enter a quantity. Once this quantity is reached, the additional costs are allocated to the remaining quantity. |

| After ... a | Selecting this option enables you to enter the number of years of production planning after which the additional costs are allocated to the remaining quantity. |

| Entry field | |

| Internal |

The internal rate indicates how much % belong to the additional costs of the supplier. Entering the internal rate influences the calculation of the external rate and vice versa. Example

The internal rate is 0, if a tool is directly paid by the customer and will therefore be the customer's property. In that case, the additional costs are not depreciated via the part price but need to be directly depreciated (relevant for investment calculation). |

| External | The external rate is the counterpart to the internal rate (1 - Internal). |

The number of pieces to build a component is taken into consideration when allocating additional costs by piece and year.

"Interest" group

| Checkbox | Description |

|---|---|

| Use capital return | Activate the checkbox to automatically use this exchange rate table when creating a costing type. Relevant entries for the interest calculation are possible. |

| Use duration of project |

|

| Use interest rate on capital of the project location |

|

You may award interest on capital multiple times in one year. To do this, enter a decimal number in "Interest period" input field.