Calculate Sawing

The Sawing cost model functions as a demo cost model that has been created in the FACTON Cost Model Designer (CMD).

All used machines, materials, and sawing times are merely hypothetical as they are only used to illustrate the cost model. Thus, the Sawing cost model is not entitled to be technically complete.

In the FACTON CMD, you can adapt the Sawing cost model to your own needs.

A special feature of this cost model is that you can enter all required values in the Details view of the Part. Based on your entries, the BoM structure of the cost model is being automatically created via the »Complete Structure« function.

For example, you can define:

- the Material Classification of the material.

- This selection provides a filtered/reduced list of corresponding material to be chosen next.

- the Pole Shape (round/rectangular) of the material.

- This selection enables the corresponding calculation type.

- The pole shape »Round« requires entering the pole diameter.

- The pole shape »Rectangular« requires entering the height and width.

- This selection enables the corresponding calculation type.

- whether the pole has a hollow profile or not

Hollow Profile: This property requires entering the wall thickness.

Hollow Profile: This property requires entering the wall thickness. Hollow Profile

Hollow Profile

- how long the Desired Part Length is.

The Sawing cost model calculates the surface of the pole that is to be sawn. This surface value calculates the sawing time per piece using defined value rules.

Sequence

The following example illustrates the process and structure of the Sawing cost model.

Step 1: Import Master Data

You can find the Excel template for importing Sample Master Data for materials and machines in the Release folder.

Import the Excel template »ScSawingMasterDataTemplate.xlsx«

| Excel template: Sawing Master Data |

Further Information ► Step 1: Import Master Data

Step 3: Insert Part

You enter all required values of the cost model in the Details view of the part. Selecting the material classification provides a filtered/reduced list of corresponding material to be chosen next.

Insert Part

- Select the should cost calculation in the Structure view.

- In the ribbon, click on Edit ►

Part (Piece) to insert a part.

- In the Details ► Overview view schema (combobox), enter values for the following properties:

| Material Classification: | Basic Materials » Metal » Steel » Quality Steel Alloyed |

|

This selection provides a filtered/reduced list of corresponding material to be chosen next. |

|

| Calculation | |

| Valuation | *Aggregate Costs |

| Manufacturing Valuation | Calculate Sawing |

|

This selection provides the new group Manufacturing Valuation with further properties. |

|

| Manufacturing Valuation ► Material | |

| Pole | e. g. Ferrous Metals (Shape: Round; Dim: 6000x20) |

| Pole Shape | Round |

| Pole Diameter | 50 mm |

| Hollow Profile |

|

| Wall Thickness | 30 mm |

| Desired Part Length (Semifinished Material) | 200 mm |

Step 4: Complete Structure

After defining all necessary values at the part, FACTON lets you create a BoM structure automatically using the »Complete Structure« function.

Complete Structure of Sawing Cost Model

- In the Structure view, select the

Part (Piece).

- Right-click on it ► Complete Structure.

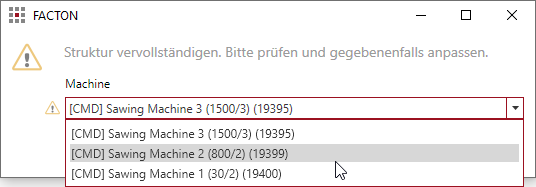

- Select a band saw machine.

Three band saw machines are offered in a combobox, all matching the selected material. The value of »Clamping Diameter« of the machines is matching the material diameter to be processed.

- Confirm your selection with OK.

Alternative: F11 in the Structure view or Details view.

Based in your selecting, a structure is automatically completed.

Properties of the Sawing cost model (Part ► Calculation ► Manufacturing Valuation)

Material Group

The material properties used to calculate the cost model are shown in this group.

Pole

Selection of pole material.

|

|

|

Pole Material Classification

Shows the classification of the selected pole material.

Pole Shape

Choose between round and rectangular. The selection shows additional required entry fields for you to fill with values.

| Round | Enter »Pole Diameter« |

| Rectangular | Enter »Height« and »Width« |

|

|

|

Pole Diameter

Diameter of the pole in mm.

|

|

|

»Hollow Profile« checkbox

Selection whether it has a hollow profile or not. If the pole material has a hollow profile, you can specify the wall thickness.

When this checkbox is activated, you need to enter a value for »Wall Thickness«.

Wall Thickness

Select a value for the wall thickness out of the combobox. The wall thickness is the spread between inner and outer pole dimensions. The wall thickness value is displayed in »mm« and its maximum is »1500 mm«.

Surface

The surface of the pole to be sawn is calculated. Based on the surface value, the sawing time per piece is determined using defined value rules (see Master Data workspace ► Global Properties ► Cost Model: Sawing ► Sawing Time).

Is calculated from:

|

Round &

|

|

|

Round &

|

|

|

Rectangular &

|

|

|

Rectangular &

|

|

Clamping Diameter

Displays the diameter of the clamping relevant for the machine. Is calculated from:

| Pole Shape | Clamping Diameter |

| Round | Value equals the »Pole Diameter«. |

| Rectangular | Value equals the smaller side of »Height« and »Width«. |

First Cut

Required first cut of the pole material. The value »15 mm« is set by default. You can directly override this value. (Predefined Value)

When you remove your value, the default value »15 mm« is set again.

|

|

|

Last Cut

Is a master data value of the machine.

In the Details view, this value is shown for the last cut of the pole. This value is determined and is depending on the selected machine.

Saw Blade Width

Is a master data value of the machine.

In the Details view, this value is shown for the saw blade width of the machine. This value is determined and is depending on the selected machine.

Pole Length (Semifinished Material)

Length of the pole material. The value »6000 mm« is set by default. You can directly override this value. (Predefined Value)

When you remove your value, the default value »6000 mm« is set again.

Desired Part Length (Semifinished Material)

The required size (length) of the final product.

|

|

|

Net Length

Shows the calculated net length of the pole material.

Is calculated from:

Calculated Output per Semifinished Material

Shows the calculated (theoretical) output per semifinished material.

Is calculated from:

Output per Gross Profile

Shows the actual (theoretical) output per semifinished material. This value represents the rounded-down value of »Calculated Output per Semifinished Material«.

Process

This group shows the process properties that are included in the calculation of the cost model.

Pole Handling Time

Shows the handling time of the pole material while sawing. The value »10 s/cycle« is set by default. You can directly override this value. (Predefined Value)

When you remove your value, the default value »10 s/cycle« is set again.

Sawing Time

The sawing time is determined for the process. Based on the surface value, the sawing time per piece is determined using defined value rules (see Master Data workspace ► Global Properties ► Cost Model: Sawing ► Sawing Time).

Total Cycle Time

Shows the total handling time for sawing.

Is calculated from:

Machine Group

The machine properties used to calculate the cost model are shown in this group.

Saw Blade Width

Is a master data value of the machine.

In the Details view, this value is shown for the saw blade width of the machine. This value is determined and is depending on the selected machine.

Last Cut

Is a master data value of the machine.

In the Details view, this value is shown for the last cut of the pole. This value is determined and is depending on the selected machine.