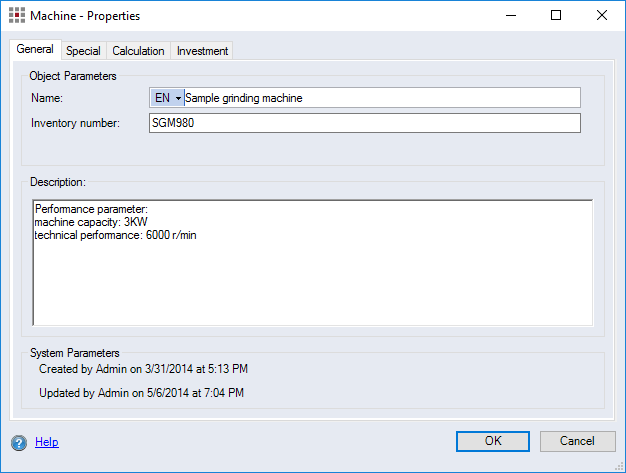

"Machine - Properties" dialog

This dialog allows you to define all of the machine properties required for calculating a project-specific machine hourly rate.

Open "Machine - Properties" dialog

- Right-click on a project-specific machine > Properties

.

.

Alternative: Select the project-specific machine and use shortcut F2.

"General" tab

The "General" tab contains the master data for the machine - including the name, the inventory number and a description of the machine.

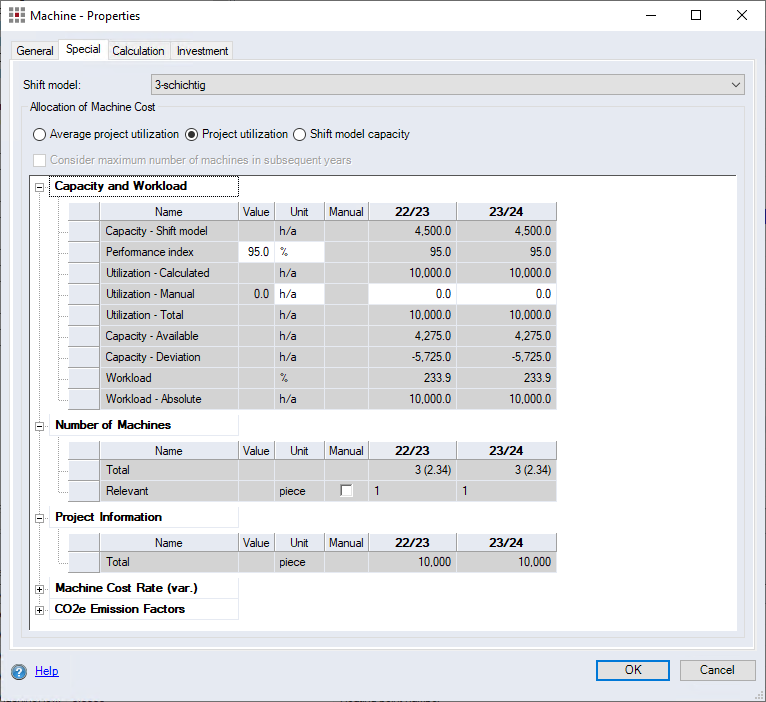

"Special" tab

The "Special" tab enables you to define the machine properties for allocation, e.g. shift model, capacity and performance rate.

"Location" comboboxes

These comboboxes are only available after activating the System Settings > Project Specific Machine > "Machine Locations" group.

Set the calendar year in the first combobox and the location where the machine is used in the second combobox.

"Shift model" combobox

Set the shift model used for the machine. For machines from Data Administration, the allocated and active shift model is preset.

"Allocation of Machine Cost" group

You can set the method for allocating machine costs in this group and display the consumption parameters for the machine hour rate.

-

"Average project utilization" option

The allocation is calculated using the average utilization for the machine for the duration of the project. The machine hour rate remains constant throughout the duration of the project.

-

"Project utilization" option

The actual annual utilization of the machine is taken into account. The machine hour rate is calculated for each year.

-

"Shift model capacity" option

The allocation type listed under shift model is used. If no shift model has been specified, you can enter the value manually into the "Capacity - Shift model" value field.

-

"Consider maximum number of machines in subsequent years" checkbox

When this checkbox is activated, the number of machines from the year with the highest value in the "Number of Machines > Relevant" row is applied to the subsequent years.

The checkbox can only be activated if the system settings are changed to ensure that the number of machines should be considered for the machine cost rate calculation.

Further Information see System Settings > "Utilization" group.

Machine capacity table

This table displays various parameters of the machine hour rate calculation for the duration of the project.

-

"Capacity and Workload" level

This level shows the machine capacity, utilization and workload for the duration of the project, i.e. for each calculation year.

Column Description Years (bold font)

Shows the values of the machine in the current project.

Years (normal font) Shows the values of the referenced machine in the external project.

| Row | Description |

|---|---|

|

Capacity - Shift Model |

Shows the maximum capacity of the machine depending on the shift model in hours per year. The maximum capacity of a machine is an absolute value that describes how many hours a machine can operate per year. The maximum capacity can only be entered manually when no shift model is selected. |

| Performance Index |

Shows the percentage factor for the performance rate. The performance rate describes the percentage of the maximum capacity that can actually be used, minus maintenance and downtime. |

|

Utilization - Manual |

Shows the manual utilization of the machine in hours per year. The manual utilization is an absolute value that describes how many hours a machine is used per year. If you activate the checkbox you can manually enter the utilization for each individual production year. Note

The manual utilization is used to calculate the machine hour rates when using "Retain the same values when released" for machine references. For further information, see "Select External Projects" dialog. |

|

Utilization - Total |

Shows the total utilization of the machine in hours per year. It is the product of the workload multiplied by the available capacity. The total utilization is an absolute value that describes how many hours a machine is used per year. |

|

Capacity - Available |

Displays the available capacity in hours per year. It is the product of the performance index multiplied by the machine capacity. The available capacity is an absolute value that describes how many hours a machine can actually be utilized per year. |

|

Capacity - Deviation |

Shows the capacity deviation between the total and the available capacity in hours per year. The workload is an absolute value that describes how many hours a machine is free per year. |

|

Workload |

Shows the percentage machine workload measured by the available capacity. The value is calculated. You can only enter the workload manually if you select the "Shift model capacity" option. |

|

Workload - Absolute |

Shows the absolute workload of the machine in hours per year, measured by the available capacity. The machine workload is calculated. You can only enter the workload manually if you have selected the "Shift model capacity" option. |

-

"Number of Machines" level

This level shows the theoretical number of machines required for the workload of each calculation year - rounded and not rounded.

Row Description Position

Shows the number of required machines for the usage position in the project.

Project Shows the number of required machines for the entire project.

Total Shows the number of required machines for all references of this machine across all cross-project positions of these machines.

Relevant Shows the relevant number of required machines. The relevant number is used to calculate the workload and the machine cost rate.

The relevant number can be calculated or manually overwritten (it then corresponds to the total number of machines).

NoteIf you overwrite the relevant number of machines, then changes in the project can no longer be considered when calculating the machine cost rates.

The relevant number of machines cannot be overwritten if the machine cost rate calculation is performed on the basis of shift model allocation or the system settings were not configured to consider the number of machines.

For more information, see Project-specific machines.

-

"Project Information" level

This level shows the production quantities for the machine per calculation year.

Row Description Total Quantity

Shows the total quantity for all references of the machine.

Project Quantity Shows the total quantity in the project.

-

"Machine Cost Rate (var.)" level

This level shows the fix machine cost rates per hour (from the "Calculation" tab) for each calculation year. The variable share of the machine cost rates are shown in brackets.

Row Description Imputed Interest

Shows the imputed interest rate.

Imputed Depreciation

Shows the imputed depreciation rate.

Energy demand

Shows the cost rate for the energy demand of the machine.

Footprint

Shows the cost rate for the footprint of the machine.

Gas demand

Shows the cost rate for the gas consumption of the machine.

Water demand

Shows the cost rate for the water consumption of the machine.

Repair demand

Shows the cost rate for the repair demand of the machine.

Resource demand

Shows the cost rate for the resource demand of the machine.

Auxiliary means demand

Shows the cost rate for the auxiliary means demand of the machine.

Total

Shows the sum of all variable shares of the machine cost rate.

-

"CO2e Emission Factors" level

This function is only available with the license "Sustainable Product Costing" (SPC Sustainable Product Costing (SPC)).This level shows the CO2 emission-relevant values of the consumption and demand parameters of the for each calculation year.

Row Description Energy demand

Shows the CO2e emission factor of the energy demand of the machine in gram per hour.

Footprint

Shows the CO2e emission factor of the footprint of the machine in gram per hour.

Gas consumption

Shows the CO2e emission factor of the gas consumption of the machine in gram per hour.

Water consumption

Shows the CO2e emission factor of the water consumption of the machine in gram per hour.

Total Shows the sum of all CO2e emission factors in gram per hour.

Emission per part Shows the CO2e emission factor in gram per piece.

You can copy the contents of the table and paste them into Excel for editing.

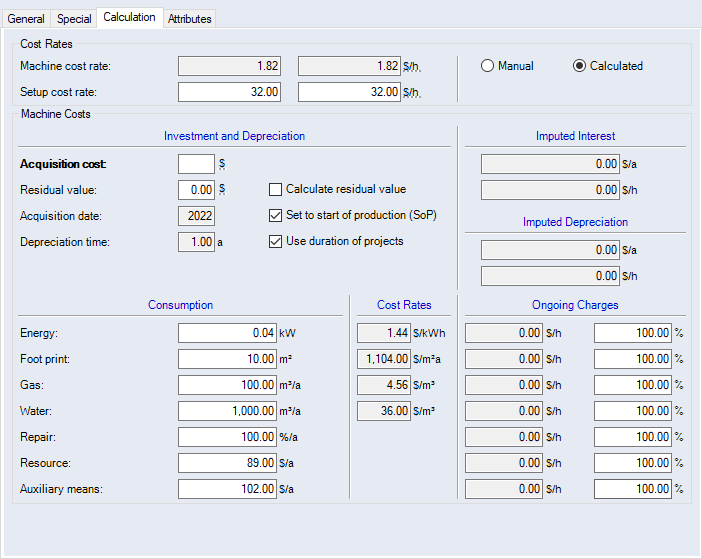

"Calculation" tab

The relevant costs for machine allocation are defined on the "Calculation" tab.

"Cost Rates" group

Here you can decide whether manufacturing rate should be calculated or entered manually. The setup cost rate must always be specified manually. The total cost rate is saved in the left text field and the right text field contains the variable cost rate for setup.

Further Information for calculating, see Calculate the cost rate.

As part of the Sustainable Product Costing you can also enter or calculate a cost rate for the CO2 emission of the machine. For further information see "CO2e Emission Factor" entry/output field.

"Machine Costs" group

"Investment and Depreciation" sub-group

The machine's investment costs are indicated in this group.

-

"Acquisition cost" entry/output field

Enter or display the acquisition cost of a new machine. If the project-specific machine already exists in the Data Administration, the current replacement costs are shown.

-

"Residual value" entry/output field

Enter or display the residual value of the machine.

-

"Calculate residual value" checkbox

Activate this checkbox to calculate the residual value. Depending on the default system settings, the residual value is either displayed only or is dynamically considered in the calculation.

Further Information "Default Settings Depreciation" group

-

-

"Acquisition date" entry/output field

Enter or display the year in which the machine was purchased.

-

"Set to start of production (SOP)" checkbox

Activate the checkbox to use the SOP year as acquisition date.

-

-

"Amortization time" entry/output field

Enter or display the number of years in which the depreciation takes place.

-

"Use duration of projects" checkbox

Activate the checkbox to automatically calculate the depreciation time with regard to the project lifetime.

-

"Imputed Interest" sub-group

Machine costs can have an imputed interest component. Which means: If a machine was not acquired, this interest could have been generated. The interest costs are added to the costs of the machine.

-

The first output field shows costs per year [EUR/a].

-

The second field shows costs per hour of the imputed interest [EUR/h].

The calculation is based on the interest rate for the linked location of the machine. If no location is linked, no calculation will be carried out and no interest will be charged.

"Imputed Depreciation" sub-group

The linear imputed depreciation from the replacement costs is calculated without the unallocated share over the indicated years. The costs are calculated for the years of depreciation from the year of acquisition.

-

The first output field shows costs per year [EUR/a].

-

The second field shows costs per hour of the linear imputed depreciation [EUR/h].

The calculation is based on the values of the "Investment and Depreciation" group.

"Demand / Consumption" group

Enter the consumption parameters for the machine hour rate costs.

-

"Energy demand" input field

The energy required for the machine.

-

"Footprint" input field

Enter the footprint required for the machine.

-

"Demand of repair" input field

Enter the share of investment costs required for repairs.

-

"Gas demand" input field

Enter the gas consumption per year.

-

"Water demand" input field

Enter the water consumption per year.

-

"Resource demand" input field

Enter the costs of auxiliary means per year required for operating the machine.

-

"Demand of auxiliary means" input field

Enter the costs of auxiliary means per year required for operating the machine.

Customize FACTONThe demand and consumption types are configured within the scope of FACTON Customizing or by an authorized partner.

"Cost Rates" sub-group

The text fields show the cost rates for the respective consumption parameters taken from the assigned location for the machine.

"Ongoing Charges" sub-group

Information on the running charges for the respective locational consumption parameter calculated from the demand and consumption cost along with the location cost rates. The input fields in the back allow you to enter the variable portion of machine costs in percent.

The static machine costs for investment, depreciation and consumption as well as the machine cost rates can be edited in the folder view of the machine (folder of the machine in Data Administration > "Special" tab).

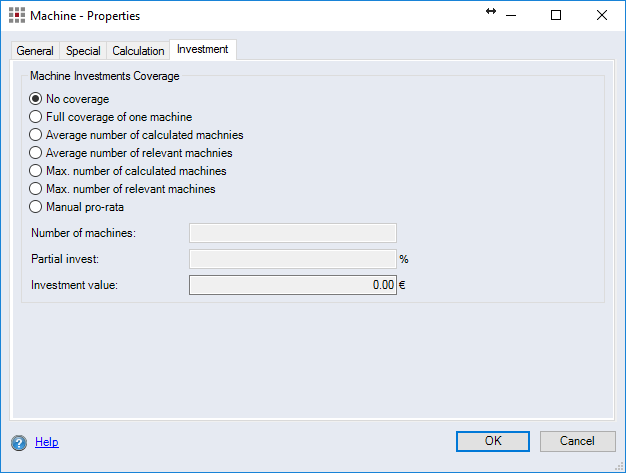

"Investment" tab

The "Investment" tab is not available to users who do not have full access rights to the "Capital Efficiency Analysis" function in the "Rights Administration" dialog.

"Machine Investments Coverage" group

In this group, define what portion of replacement costs should be included as an investment. The result of the difference of replacement costs and the portion of replacement costs not used in costing is multiplied by a factor you selected in advance. The replacement costs appear in the "Investment" category dialog.

-

"No coverage" option

The surcharge is not included in the investment calculation. There is no additional entry in the investment dialog.

-

"Full coverage of one machine" option

Total replacement costs of one machine less non-absorbed costs are considered as an investment in the investment calculation.

-

"Average number of calculated machines" option

The replacement costs are determined based on the average number of machines in the "Number of Machines, Total" row.

-

"Max. number of calculated machines" option

The replacement costs are determined based on the average value of the calculated machines. The costs are considered as an investment in the investment calculation.

-

"Max. number of relevant machines" option

The replacement costs are determined based on the average value of the relevant machines. The costs are considered as an investment in the investment calculation.

NoteThe relevant number of machines is a rounded value. It can be overwritten.

-

"Manual input" option

Define the portion of the replacement costs to be taken into account within the scope of the investment.

-

"Number of Machines" input field

Enter the manual number of machines to be considered in the investment calculation.

-

"Partial investment" input field

Enter the share of the machine costs to be considered in the investment calculation.

-

"Investment value" input field

Displays the calculated costs to be considered as an investment in the scope of the investment calculation.

-