Calculate Machining

You can use the Calculate Machining cost model for calculating the process times and costs for the chipping manufacturing method in metal working. In FACTON, there are value rule tables and formulas defined at the cost model providing you with information on:

- the anticipated cycle time,

- the possible process output per time and cycle,

- the material consumption

- the cutting speed and feed per tooth, and

- the primary and secondary processing times.

You need knowledge of the

Sequence

The following example illustrates the process and structure of the

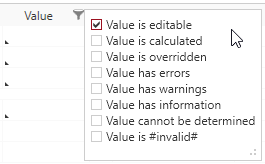

The black triangle ◣ helps you identify editable values.

The Consistency Rule Violation check is available to you when entering values. The consistency rule violations check notifies when there are missing values and verifies the accuracy of the values entered.

When you hover over one of the Consistency rule violations icons with your mouse, a tooltip appears with the specific reason for the consistency rule violations.

Step 1: Create Should Cost Calculation

Further Information > Create Should Cost Calculation

Step 2: Insert Part

- Select the

should cost calculation in the Structure view.

should cost calculation in the Structure view. -

In the ribbon, click on Edit > Insert >

Part (Piece).

A part is inserted in the calculation structure.

- Define the following properties in the Details (General Properties

view scheme) view:

| Material Classification* | Basic Material > Metal > Steel > Stainless Steel Unalloyed |

| Manufacturing Method* | Separating > Chipping with Geometrically Determined Cutting Edge |

| *FACTON recommends the matching materials and machines according to your choices in the material classification and manufacturing method. | |

You can use the following

| Material Classification |

|---|

| Steel |

| Steel with Special Physical Properties |

| Alloyed Steel / Construction Steel / Chemical Resistant Steel |

| Special Purpose Steel |

| Cast Iron |

| Nonferrous Metal |

| Titanium Alloy |

| Plastic Materials |

Step 3: Insert Process

- Select the

part in the Structure view.

-

In the ribbon, click on Edit > Insert >

Process.

A process is inserted in the calculation structure.

-

In the Details view (Calculation view scheme

), select the manufacturing valuation Calculate Machining.

A new group Manufacturing Valuation appears with sub-groups.

-

In the Details view, click on the filter symbol and activate the checkbox for the values to be entered.

-

For example, enter the following values:

Material Material Selection C20E2C (Cq22) Input Weight 1 kg Finished Weight 0.6 kg Machine Machine Selection CNC Vertical Machining Center | Rotation speed: < 6,000.00 1/min | parts weight: < 2,000.00 kg

A matching machine is being determined based on the calculated values for clamping force and shot volume.

Worker Labor Group Unskilled

The corresponding labor costs for the worker are determined based on the reference location, reference date, and the labor group of the worker.

Number of Workers 1 Fixtures Fixture Cost 2,500.00 EUR % Fixture Maintenance 2 %/a

Step 4: Complete Structure

Based on your entries, the BOM structure of the cost model is being automatically created via the "Complete Structure" function.

Complete Structure of the Cost Model

- In the Structure view, select the

process.

- Right-click on it > Complete Structure.

Alternative: F11 in the Structure or Details view.

The structure is automatically completed based in your entries.

Further changes are not applied immediately.

Perform the "Complete Structure" action again to update your cost model.

Step 5: Insert Work Steps

A range of separate work steps is required in order to manufacture a component in the chipping process. To visualize complex machining parts in detail, they must be broken down into separate work steps. With FACTON, you can define multiple work steps at the Machining cost model.

Insert Work Steps

- In the Structure view, right-click on the

process.

-

Select Insert New >

Work Step (Cycle).

Work Step (Cycle).The work step is inserted into the calculation structure.

-

In the Details view (Calculation view scheme

), select the manufacturing valuation Milling: Face Milling.

A new group Input Parameters with sub-groups is shown.

-

For example, enter the following values:

Geometrical Parameters Facing Width 100 mm Stripping Length 100 mm Stripping Height 60 mm Tool Parameters Tool Travel (Overtravel, Start-Up) 10 mm Tool diameter 6 mm Other Parameter Tool Changing

Length of Tool Movement (Non-Cutting) 100 mm -

In the Details view (Calculation view scheme

), select the manufacturing valuation Turning: Threading.

A new group Input Parameters with sub-groups is shown.

-

For example, enter the following values:

Geometrical Parameters Thread Selection M5*0.8 Thread Length 120 mm Tool Parameters Tool Travel (Overtravel, Start-Up) 15 mm Other Parameter Tool Changing

Tool Indexing

Length of Tool Movement (Non-Cutting) 120 mm