Calculate Injection Molding

You can use the Calculate Injection Molding cost model to calculate the process times and costs for the injection molding manufacturing process in plastics processing. In FACTON, there are value rule tables and formulas defined at the cost model providing you with information on:

- the anticipated cycle time,

- the possible process output per time and cycle,

- the material consumption,

- the clamping force and the shot volume of the machine, and

- the primary and secondary processing times.

The table shows typical application scenarios of the cost model for parts and industry:

| Typical Parts | Typical Industries |

|---|---|

|

|

You need knowledge of the

Sequence

The following example illustrates the process and structure of the

The black triangle ◣ helps you identify editable values.

The Consistency Rule Violation check is available to you when entering values. The consistency rule violations check notifies when there are missing values and verifies the accuracy of the values entered.

When you hover over one of the Consistency rule violations icons with your mouse, a tooltip appears with the specific reason for the consistency rule violations.

Step 1: Create Should Cost Calculation

Further Information > Create Should Cost Calculation

Step 2: Insert Part

- Select the

should cost calculation in the Structure view.

should cost calculation in the Structure view. -

In the ribbon, click on Edit > Insert >

Part (Piece).

A part is inserted into the calculation structure.

- Enter the following property values for the part in the Details view (General Properties

view scheme):

| Material Classification* | Basic Material > Plastic Material > Thermoplast > ABS - Acrylnitril-Buthadiene-Styrene |

| Manufacturing Method* | Primary Shaping > Casting > Injection Molding |

| *FACTON recommends the matching materials and machines according to your choices in the material classification and manufacturing method. | |

You can use the following

For Thermoplast (Basic Materials > Plastic Material > Thermoplast):

- PE - Polyethylene > PE-HD - Polyethylene high density

- PE - Polyethylene > PE-HD - Polyethylene low density

- PP - Polypropylene

- PA - Polyamide > PA 6 - Polyamide 6

- PA - Polyamide > PA 66 - Polyamide 66

- PA - Polyamide > PA 11 - Polyamide 11

- PA - Polyamide > PA 12 - Polyamide 12

- PA - Polyamide > PPA - Polyphthalamide

- PS - Polystyrene

- ABS - Acrylnitrile-Buthadiene-Styrene

- SAN - Styrene-Acrylnitrile

- ASA - Acrylonitrile Styrene Acrylate

- PC - Polycarbonate

- PC / ABS - Polycarbonate/Acrylnitrile Buthadiene Styrene

- PVC - Polyvinylchloride > PVC-U - Polyvinylchloride Unplasticized (hard)

- PVC - Polyvinylchloride > PVC-P - Polyvinylchloride Plasticized (soft)

- PMMA - Polymethyl methacrylate

- PET - Polyethylene terephthalate

- PBT - Polybutylene terephthalate

- POM - Polyoxymethylene

- PPE/PA - Polyphenylene ether/Polyamide

- PSU - Polysulfone

- PES - Polyethersulfone

- CA - Cellulose acetate

- CP - Cellulose proprionate

- CAP - Cellulose acetopropionate

- CAB - Cellulose acetobutyrate

- PTFE - Polytetrafluoroethylene

- ETFE - Ethylene tetrafluorethylene

- FEP - Tetrafluorethylene/Hexafluorpropylene

- PCTFE - Polychlortrifluorethylene

For Elastomers (Basic Materials > Plastic Material > Elastomer):

- EVA - Ethylene Vinyl Acetate

Step 3: Insert Process

- Select the

part in the Structure view.

-

In the ribbon, click on Edit > Insert >

Process.

A process is inserted in the calculation structure.

-

In the Details view (Calculation view scheme

), select the manufacturing valuation Calculate Thermoplastic Injection Molding.

The process is automatically renamed to "Injection Molding".

A new group Manufacturing Valuation appears with sub-groups.

-

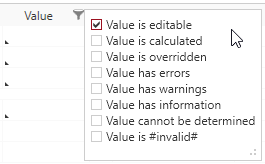

In the Details view, click on the filter symbol and activate the checkbox for the values to be entered.

-

For example, enter the following values:

Input parameters Runner Type Hot Runner Cavity Count selected 2.00 pc/cycle Component 1 Material Classification is automatically assumed from the

part

Material Selection ABS - Granules

After selecting, the density and other material parameters are shown.

Part (Component) Weight 0.1 kg/pc Projected Area of Part 50 cm²/pc Maximum Wall Thickness 3 mm Machine Selection A matching machine is being determined based on the calculated values for clamping force and shot volume.

You can also choose a different machine from the combobox.

Labor Group Unskilled

The corresponding labor costs for the worker are determined based on the sector, the reference location, the reference date, and the labor group.

Number of Workers 2 -

Enter some more values for other process parameters, tools and fixtures.

Other Process Parameters Slider Type Mechanical Slider Insertion Parts Necessary

Part Removal Type Robot Unload

A further property for selecting the robot unloading type.

Unload Robot Industrial robot | Payload: 6.00 kg | Reach: < 1,820.00 mm Tools and Fixtures Tool Cost 25,000.00 EUR % Tool Maintenance 2 %/a Fixture Cost 2,500.00 EUR % Fixture Maintenance 2 %/a

Based on the selected material classification you can choose a material in the material selection. Accordingly, the following property values are determined via value rules:

- Density

- Available Clamping Force

- Melt Temperature

- Tool Temperature

- Demolding Temperature

- Defusion Rate

The properties are shown at the process in the Details view (Calculation view scheme ) under Manufacturing Valuation > Miscellaneous Parameters > Component 1 > Material.

Step 4: Complete Structure

Based on your entries, the BOM structure of the cost model is being automatically created via the "Complete Structure" function.

Complete Structure of the Cost Model

- Select the

process in the Structure view.

- Right-click > Complete Structure.

Alternative: F11 in the Structure view or Details view.

Based in your selection, a structure is automatically completed.

Further changes are not applied immediately.

Perform the "Complete Structure" action again to update your cost model.

Properties of the Injection Molding cost model (Calculation > Manufacturing Valuation)

Input Parameters group

The general cost model parameters that are actively entered for precise definition are displayed in this group.

Runner Type

Selection of the runner type method: Cold or hot runner.

![]() Selection from list directly possible.

Selection from list directly possible.

Cavity Count Suggested

The recommended number of cavities per cycle according to the parameters.

Depends on:

- Runner Type

- Projected Area of Part (under "Input Parameters > Component 1 or 2")

Indirect input is possible using F12.

Cavity Count Selected

The actually chosen number of cavities per cycle.

![]() Direct input is possible.

Direct input is possible.

Multicomponent Injection Molding

Selection of an additional component to be manufactured by injection molding. When the checkbox is activated, an additional sub-group "Component 2" appears under "Input parameters" with the same properties as for component 1.

![]() Activating/deactivating directly possible via a checkbox.

Activating/deactivating directly possible via a checkbox.

Machine Selection

Select a machine. A suitable selection list of machines is provided and pre-selected on the basis of the entries made for the component.

Depends on:

- Cavity Count Selected

- Part (Component) Weight (under "Input Parameters > Component 1 or 2")

- Max. Wall Thickness (under "Input Parameters > Component 1 or 2")

|

|

|

Labor Group

Selection of the labor group the machine operator belongs to.

![]() Selection from list directly possible.

Selection from list directly possible.

Number of Workers

Number of workers operating the machine.

![]() Direct input is possible.

Direct input is possible.

Number of Parallelly Operating Work Stations

Number of work stations in injection molding cycle that can be parallelly operated.

Indirect input is possible using F12.

Component 1 group (under "Input Parameters")

In this group, the material-specific properties for the first component (part) to be included in the calculation of the cost model are displayed (if "Multicomponent Injection Molding" is activated, this group is additionally available for "Component 2").

Material Classification

Selection of the material classification as basis for selecting the material. Usually the selection is made in the General Properties view schema and will then be assumed to the "Material" group in the Calculation view schema.

Under Details > General Properties:

|

|

|

Under Details > Calculation:

Indirect input is possible using F12.

Material Selection

Selection of the material.

|

|

|

Density

Density of the material.

This value is required.

This value can be managed at the material (Details > Technical Data view scheme), or is applied when global templates are inserted.

Indirect input is possible using F12.

% Gating (Sprue) Volume

Percentage volume of the gating system. The property is only available if the "Runner Type" (under "Input Parameters") is set to "Cold Runner". By default, the value "5.00 %" is predefined.

![]() Direct input is possible.

Direct input is possible.

Gating System Volume

Absolute volume of the gating system. The property is only available if the "Runner Type" (under "Input Parameters") is set to "Cold Runner".

Is calculated from:

- Cavity Count Selected (under "Input Parameters")

- Density

- % Gating (Sprue) Volume

- Part (Component) Weight

Indirect input is possible using F12.

Part (Component) Weight

Weight of the component (1 or 2) per piece.

![]() Direct input is possible.

Direct input is possible.

Projected Area of Part

The area of the part projected in the mold parting surface.

![]() Direct input is possible.

Direct input is possible.

Max. Wall Thickness

Maximum wall thickness of the part.

|

|

|

Other Process Parameters group

The cost model parameters that can be entered for further definition are displayed in this group.

Slider Type

Selection of the slider type: Mechanical or hydraulic slider.

![]() Selection from list directly possible.

Selection from list directly possible.

Insertion Parts Necessary

Choice if additional insertion parts are required for the cycle.

![]() Activating/deactivating directly possible via a checkbox.

Activating/deactivating directly possible via a checkbox.

Parts Insertion Time

Time required for inserting the parts. Is calculated if "Insertion Parts Necessary" was activated. By default, the value "5.00 s/cycle" is predefined.

Indirect input is possible using F12.

Part Removal Type

Selection of the method how the parts are to be removed.

(If the value "Robot unload" is selected, an additional property for selecting an "Unload Robot" from the master data is available).

![]() Selection from list directly possible.

Selection from list directly possible.

Two Plate Ejector

Choice if an ejector for two plates is required in the cycle.

![]() Activating/deactivating directly possible via a checkbox.

Activating/deactivating directly possible via a checkbox.

Multicomponent Technology

Selection of a method for the multicomponent injection molding process. Is only available if the property "Multicomponent Injection Molding" was activated.

![]() Selection from list directly possible.

Selection from list directly possible.

Tools and Fixtures group (under "Input Parameters")

In this group you can define the costs for tools and fixtures, as well as their annual maintenance costs.

Tooling Cost

Costs required for used tools.

![]() Direct input is possible.

Direct input is possible.

% Tooling Maintenance

Share of maintenance costs for tools per year.

![]() Direct input is possible.

Direct input is possible.

Fixture Cost

Costs required for used fixtures.

![]() Direct input is possible.

Direct input is possible.

% Fixture Maintenance

Share of maintenance costs for fixtures per year.

![]() Direct input is possible.

Direct input is possible.

Calculated Parameters group

This group displays the cost model parameters that are calculated with regard to the clamping force and machine properties.

Clamping Force group (under "Calculated Parameters")

The clamping force properties used to calculate the cost model are shown in this group.

Clamping Force by Projected Area of Part

Clamping force by projected area of part in the mold parting surface.

Is calculated from:

- Specific Clamping Force

- Projected Area of Part

% Additional Clamping Force for Safety

Percentaged additional clamping force for safety ratio by projected area. Is calculated when entering a value for the "Additional Clamping Force for Safety".

![]() Direct input is possible.

Direct input is possible.

Additional Clamping Force for Safety

Absolute additional clamping force for safety ratio by projected area. Is calculated when entering a value for the "% Additional Clamping Force for Safety".

% Additional Clamping Force for Sliders

Percentaged additional clamping force for sliders by projected area. Is calculated when entering a value for the "Additional Clamping Force for Sliders".

![]() Direct input is possible.

Direct input is possible.

Additional Clamping Force for Sliders Ratio

Absolute additional clamping force for sliders by projected area. Is calculated when entering a value for the "% Additional Clamping Force for Sliders".

Required Clamping Force for Part

Required clamping force for the part with additional clamping forces.

Is calculated from:

- Clamping Force by Projected Area of Part

- Additional Clamping Force for Safety

- Additional Clamping Force for Sliders Ratio

Clamping Force by Projected Area of Gating System

Clamping force by projected area of the gating system in the mold parting surface.

Is calculated from:

- Available Clamping Force

- Projected Area of Gating System

Relevant Clamping Force

Required total clamping force for all cavities and the gating system.

Is calculated from:

- Cavity Count Selected (under "Input Parameters")

- Required Clamping Force for Part

- Clamping Force by Projected Area of Gating System

Machine group (under "Calculated Parameters")

The machine properties used to calculate the cost model are shown in this group.

Available Clamping Force

Maximum clamping force of the machine that is available.

This value is required.

This value is required and can be managed at the machine (Details > Technical Data view scheme), or is applied when global templates are inserted.

Shot Volume of the Machine

Maximum shot volume of the machine that is available.

This value is required.

This value is required and can be managed at the machine (Details > Technical Data view scheme), or is applied when global templates are inserted.

Possible Cavity Count by Clamping Force

The possible count of cavities determined with respect to the available clamping force.

Is calculated from:

- Available Clamping Force

- Clamping force according to the projected area of gating system (under "Calculated Parameters > Clamping Force").

- Required clamping force of the part (under "Calculated Parameters > Clamping Force")

Possible Cavity Count by Shot Volume

The possible count of cavities determined with respect to the available shot volume.

Is calculated from:

- Shot Volume of the Machine

- Gating System Volume (under "Input Parameters > Component 1 or 2")

- Part (Component) Volume (under "Other Parameters > Component 1 or 2 > Part")

Cavity Count Suggested

The recommended number of cavities per cycle according to the parameters. Equals the property of the same name under "Input Parameters".

Indirect input is possible using F12.

Primary Processing Times group

The primary processing times used to calculate the cost model are shown in this group.

Injection and Cooling Time

Time for injecting and cooling down the part for removal and further usage. Is calculated from:

- Injection Time (under "Other Parameters > Component 1 or 2 > Processing Time")

- Cooling Time (under "Other Parameters > Component 1 or 2 > Processing Time")

- Max. Wall Thickness (under "Input Parameters > Component 1 or 2")

- Melt Temperature (under "Other Parameters > Component 1 or 2 > Material")

- Tool Temperature (under "Other Parameters > Component 1 or 2 > Material")

- Demolding Temperature (under "Other Parameters > Component 1 or 2 > Material")

- Defusion Rate (under "Other Parameters > Component 1 or 2 > Material")

Indirect input is possible using F12.

Tool Opening and Closing Time

Time for opening and closing the tool.

Depends on:

- Available Clamping Force (under "Calculated Parameters > Machine")

Indirect input is possible using F12.

Additional Time for Multi-Component Process

Time required for a multi-component injection molding process. Is only available and calculated if the checkbox ![]() "Multicomponent Injection Molding" was activated under "Input Parameters").

"Multicomponent Injection Molding" was activated under "Input Parameters").

Indirect input is possible using F12.

Additional Primary Processing Times

Possibility to add primary processing times that have not been considered.

![]() Direct input is possible.

Direct input is possible.

Primary Processing Time

Time in which the actual activity of a process is performed.

- Injection and Cooling Time

- Tool Opening and Closing Time

- Additional Time for Multi-Component Process

- Additional Primary Processing Times

Secondary Processing Times group

The secondary processing times used to calculate the cost model are shown in this group.

Parts Insertion Time

Time for inserting the parts into the machine. Equals the property of the same name under "Input Parameters > Other Process Parameters".

Indirect input is possible using F12.

Slider Cycle Time

Time required for a slider per cycle.

Depends on:

- Slider Type (under "Input Parameters > Other Process Parameters")

Indirect input is possible using F12.

Part Unloading Time

Time for unloading the part.

Indirect input is possible using F12.

Two Plate Ejector Cycle Time

Time to eject the part if an ejector with two levels is used. Is calculated if "Two Plate Ejector" is activated under "Input Parameters > Other Process Parameters".

Indirect input is possible using F12.

Additional Secondary Processing Times

Possibility to add secondary processing times that have not been considered.

![]() Direct input is possible.

Direct input is possible.

Secondary Processing Time

Necessary idle time of a process in which its actual activity cannot be performed.

Is calculated from:

- Parts Insertion Time

- Slider Cycle Time

- Part Unloading Time

- Two Plate Ejector Cycle Time

- Additional Secondary Processing Time

Other Parameters group

Definition parameters for further specification of the individual cost model properties per component are displayed in this group.

Component 1 or 2 group (under "Other Parameters")

The specification parameters for material, part and primary processing times are managed in this group for the first or second component.

Material sub-group (Component)

Available Clamping Force

Clamping force per area for a given material.

Depends on: Material Classification

Indirect input is possible using F12.

Melt Temperature

Temperature the melted material has during injection.

Depends on: Material Classification

Indirect input is possible using F12.

Tool Temperature

Temperature of the tool which causes cooling of the melted material.

Depends on: Material Classification

Indirect input is possible using F12.

Demolding Temperature

Target temperature when cooling is finished and demolding can be done.

Depends on: Material Classification

Indirect input is possible using F12.

Defusion Rate

Factor that specifies how much area of a given material can cool down per time.

Depends on: Material Classification

Indirect input is possible using F12.

Part sub-group (Component)

Part (Component) Volume

Volume of the part. Is calculated if a value for "Part (Component) Weight" is entered under "Input Parameters > Component 1 or 2".

Indirect input is possible using F12.

Projected Area of Gating System

The area of the gating system projected in the mold parting surface. Is calculated if a value for "Projected Area of Part" is entered under "Input Parameters > Component 1 or 2".

Indirect input is possible using F12.

Material Usage

Required material weight including gating system weight. Is calculated if a value for "Material Selection" is set under "Input Parameters > Component 1 or 2".

Is calculated from:

- Density (under "Input Parameters > Component 1 or 2")

- Material Usage Volume

Material Usage Volume

Required material weight including gating system volume.

Is calculated from:

- Density (under "Input Parameters > Component 1 or 2")

- Part (Component) Weight (under "Input Parameters > Component 1 or 2")

- Sprue Weight

Sprue Weight

Required weight for gating system (sprue). Is calculated if a value for "Part (Component) Weight" is entered under "Input Parameters > Component 1 or 2".

Sprue Recycling Rate

Percentage material mass share of the gating system (sprue) that can be recycled.

Indirect input is possible using F12.

Recyclable Material

Material mass of the gating system which can be recycled. Is calculated if a value for "Material Selection" is set under "Input Parameters > Component 1 or 2".

Is calculated from:

- Density (under "Input Parameters > Component 1 or 2")

- Gating System Volume (under "Input Parameters > Component 1 or 2")

Processing Time sub-group (Component)

Injection Time

Time for the injection process per cycle. The initial value is provided from the master data.

Depends on: Material Classification

Is calculated from:

- Cavity Count Selected (under "Input Parameters")

- Density (under "Input Parameters > Component 1 or 2")

- Part (Component) Volume (under "Other Parameters > Component 1 or 2 > Part")

Indirect input is possible using F12.

Cooling Time

Time for cooling down the part for removal and further usage.

Is calculated from:

- Material Selection (under "Input Parameters > Component 1 or 2")

- Max. Wall Thickness (under "Input Parameters > Component 1 or 2")

Interface Parameters group

The interface values for the injection molding process and the component materials are listed in this group.

Process sub-group

Cycle Time

Overall time for injection molding per cycle.

Is calculated from:

- Injection Time (under "Other Parameters > Component 1 or 2 > Processing Time")

- Cooling Time (under "Other Parameters > Component 1 or 2 > Processing Time")

Cycles per Time

Shows all calculated cycles per time unit. The value is bidirectional to the value of "Cycle Time".

Output per Time

Shows the calculated output per time unit.

Material 1 or 2 sub-group

Net Quantity

Net quantity of the material of the respective component.

Is calculated from:

- Cycle Time

- Part (Component) Weight (under "Input Parameters > Component 1 or 2")

Markup Rate on Net Quantity

Percentage surcharge on the net quantity.

Is calculated from:

- % Gating (Sprue) Volume (under "Input Parameters > Component 1 or 2")

- Gating System Volume (under "Input Parameters > Component 1 or 2")