Calculate Die Casting

You can use the Calculate Die Casting cost model to calculate the process times and costs for the die casting manufacturing process in metalworking. In FACTON, there are value rule tables and formulas defined at the cost model providing you with information on:

- the anticipated cycle time,

- the possible process output per time and cycle,

- the material consumption, and

- the clamping force and the machine shot mass, and

- the primary and secondary processing times.

In the cost model Die Casting a distinction is made between hot and cold chamber processes.

The table shows typical application scenarios of the cost model for parts and industries:

| Typical parts | Typical Industries |

|---|---|

|

|

You need knowledge of the

Sequence

The following example illustrates the process and structure of the

The black triangle ◣ helps you identify editable values.

The Consistency Rule Violation check is available to you when entering values. The consistency rule violations check notifies when there are missing values and verifies the accuracy of the values entered.

When you hover over one of the Consistency rule violations icons with your mouse, a tooltip appears with the specific reason for the consistency rule violations.

Step 2: Insert Part

- Select the

should cost calculation in the Structure view.

should cost calculation in the Structure view. -

In the ribbon, click on Edit > Insert >

Part (Piece).

A part is inserted in the calculation structure.

- Define the following properties in the Details view (General Properties

view schema):

| Material Classification* | Basic Material > Metal > Nonferrous Metal > Light Metal > Aluminum |

| Manufacturing Method* | Primary Shaping > Casting > Die Casting |

| *FACTON recommends the matching materials and machines according to your choices in the material classification and manufacturing method. | |

You can use the following

| Material Classification | Die Casting Technique |

|---|---|

| Aluminum |

Cold-Chamber Die Casting is automatically set |

| Magnesium Alloy | |

| Zinc |

Hot-Chamber Die Casting is automatically set |

| Tin |

Step 3: Insert Process

- Select the

part in the Structure view.

-

In the ribbon, click on Edit > Insert >

Process.

A process is inserted in the calculation structure.

-

In the Details view (Calculation view schema

), select the manufacturing valuation Calculate Die Casting.

The process is automatically renamed to "Die Casting".

A new group Manufacturing Valuation appears with sub-groups.

-

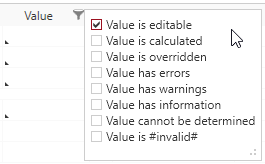

In the Details view, click on the filter symbol and activate the checkbox for the values to be entered.

-

For example, enter the following values:

Material Selection AlSi10Mg Material % Material Loss 2 % Manufacturing part Part Weight 0.50 kg/pc Gating System Volume 15 cm³/cycle Projected Area of Part 100 cm²/pc Wall Thickness 6 mm Surface Area per Part 300 cm²/pc Sliders Necessary

Clamping Force % Additional Clamping Force for Safety 10% -

Enter some further values for the machine, tools and fixtures.

Machine Machine Selection Cold chamber die-casting machine (Mg; Al) | clamp force: 3,400.00 kN | Shot mass: 2.30 - 6.40 kg

Based on the calculated values of the relevant total clamping force and the material usage weight, a matching machine is being determined.

Furnace Selection Medium frequency induction heater | Melting power: < 950.00 kg/h Secondary Processing Times Insertion and Demolding Time 5 s/cycle Tools & Fixtures Tool costs 25,000.00 EUR % Tool Maintenance 2 d / a Fixture Cost 1,500,000 EUR % Fixture Maintenance 2 d / a

Based on the selected material classification you can choose a material in the material selection. Accordingly, the following property values are determined via value rules:

- Density

- Specific Die Casting Pressure

- Thermal Conductivity

- Specific Heat Capacity

The properties are shown at the process in the Details view (Calculation view schema ) under Manufacturing Valuation > Material.

Step 4: Complete Structure

Based on your entries, the BOM structure of the cost model is being automatically created via the "Complete Structure" function.

Complete Structure of the Cost Model

- Select the

process in the Structure view.

- Right-click on it > Complete Structure.

Alternative: F11 in the Structure view or Details view.

Based in your selecting, a structure is automatically completed.

Further changes are not applied immediately.

Perform the "Complete Structure" action again to update your cost model.