Costing Schema

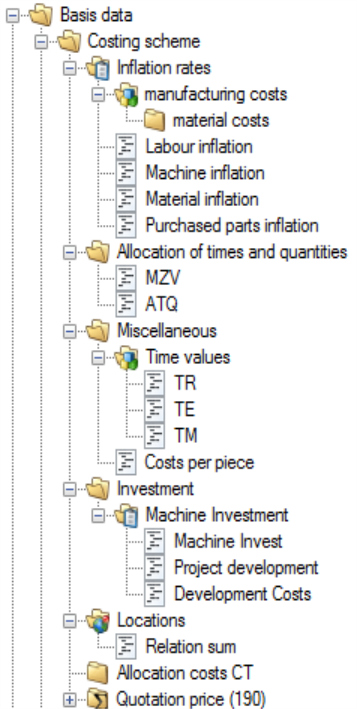

The FACTON, a costing scheme defines the computing steps required to calculate the complete costs based on the individual cost components in order to produce a total for the production costs of a product. Costs can be incurred in a project in numerous ways. This diagram lists all the costs that are predefined in FACTON:

Figure: Costing Schema

A distinction is made between costs that cannot be allocated to any particular part, but still form part of the product costs (extra charges), and costs that are directly allocated to a part (production costs).

Further cost structures can be included in the calculation using additional cost definitions (total lines) on the basis of predefined cost types. It is possible to create additional total lines per part as well as per product. The total can be calculated either by adding the existing values or by entering a calculation formula. In addition, surcharge rates, such as overheads or inflation can be added to all cost elements. Surcharges can also be defined for total lines.

Figure: Example costing scheme in FACTON (Data Administration detail)

Levels of calculation

Calculations in FACTON are divided into two levels:

| Component level | Project level |

|---|---|

|

The first level is the component level and it covers all costs and structures below the top-level assembly. Generally speaking, the cost structure is divided into material costs (MatC) + manufacturing costs (ProdC) + additional costs. The material costs and the manufacturing costs are further sub-divided. Typically, overhead costs that can be assigned to individual calculation elements are added on the component level. These are normally material and manufacturing overhead costs. |

The second level is the project level. It is used to define costs that can be incurred above the top-level assembly. Examples are sale overhead costs and administration overhead costs. In FACTON, these costs are referred to as extra charges. |