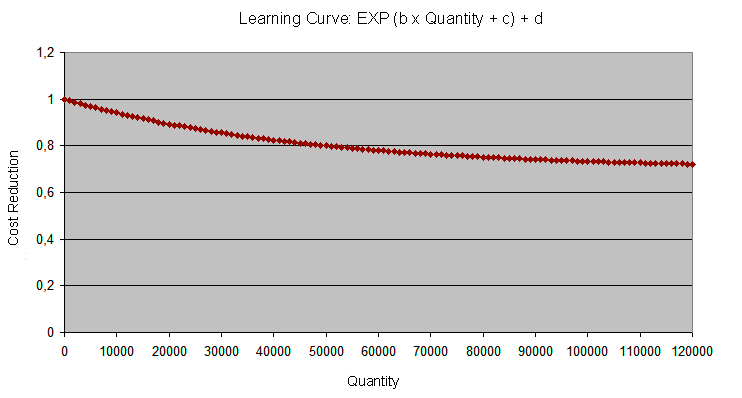

Learning curve

Learning curves are used to forecast cost reductions at a higher production quantity. The principle of the learning curve theory states that by doubling the quantity produced it is possible to achieve a cost reduction per unit by a constant percentage. The learning curve informs you how close work processes of new products are to a stage where the work is free of defects. It graphically represents the relation between required time and intended result. Labor costs per product unit may fall with increasing product knowledge.

As a result of the learning effect, the time taken to achieve the same result is reduced or a better result is achieved in the same time period.

Depending on each technology, there are different learning curve effects, e.g.

- Assembling: 30 % max.

- Injection molding: 15 % max.

Figure: Learning curve illustration

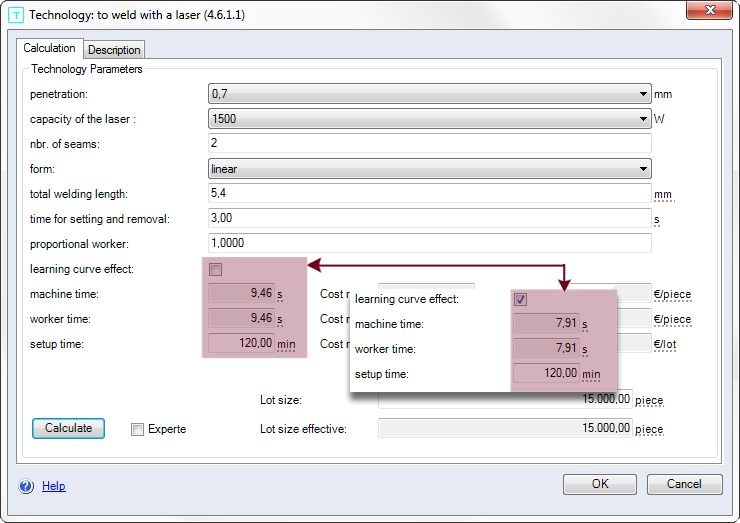

Applying the learning curve

- Open the "Technology" dialog.

- Activate the "Learning curve effect" checkbox.

The average value for machine and worker time is calculated.

Figure: Application of the learning curve in the "Technology" dialog